Lots of shoes are bought per capita – and disposed about just as quick due to "fast fashion". Many people are trapped in a vicious circle. Every month a variety of different collections are released into the market by famous fashion labels. These often cheaply manufactured and trend loaded shoes either wear out or are become boring by the end of the month, as trends often happen to be short-lived. Thus, cheap new shoes are bought in order to satisfy one's consumerism. "Fast fashion" provokes waste; the continuous cycle of buying and then throwing-away dissipates valuable resources and damages the environment on the long-term.

Most of the customers do not really think before purchasing anymore. Sadly, habitual shopping already became the norm. You see something new and you simply buy it because you can, not because you really need it.

Especially the younger generations are prone to participating in "fast fashion". The roots of this movement can be retraced to the year 1990 when Zara opened in New York. Back then, the term "fast fashion" was first used by 'The New York Times' to describe this fast-paced business model.

Solution:

One must convince the people concerned to reconsider their habits. Launching a well-designed product into the market would not tackle the problem sufficiently, as it is also subject to redundancy due to developing fashion trends, as well being washed out of the market by the next wave of "fast fashion" products. Multiple attributes are required if you want customers to rethink their behavior and notice the futility of buying numerous, similar shoes even though a single one of higher quality would be more than sufficient.

Product idea:

I want to introduce a "Slow Sneaker"; an individually customizable shoe designed to counteract said movement. Several attributes create a value proposition for the customer, unattainable for generic "fast fashion" sneakers. Close to perfect accuracy of fit ensures that the sneakers are comfortable to wear and is achieved by 3D scanning the buyer's feet beforehand. Owing to the timeless base model and various customization options, the sneaker can be transformed into many different styles, thus being immune to becoming redundant in the near future.

I started by doing a lot of research. As a first step I looked at important companys and products in the sneaker industry. I compared the different styles under aspects like color, materials, pricepoints, sustainability and customizability. I also looked at the historical backround and predecessor products.

Then I sketched a lot to gain an innovative idea for my own project. I wanted to incorporate a distinctive main shape as a characteristic feature. Many other known or unknown brands integrate these in their shoes. This patch should also act as a part, which can be used to peronalise the sneaker. Furthermore I looked into other methods on how to personalise shoes in a creative way, like charms, laces etc.

On the left you can see the sketch of my finished base design. It's a timeless sneaker, which can be worn for multiple years. Due to the simple design it can be personalised easily to fit many different styles.

The picture on the right shows the development of the patch I wanted to incorporate. Most companies on the market have their signature patch on the side of their shoes. I decided to have it on the back to stand out in this aspect.

I also extended the shape, to make it possible to attach it easily with the laces. As an additional support I added the button on the heel. It's possible to switch out the whole patch fast and easily, while it's also well secured with this three point system.

This is the paper model I made to check my design on feasibility and visual appearence.

Paper model

Paper model

Paper model

After making the paper model, I wanted to try to build a sample out of leather as well. It was really complicated, but in the end it gave a good impression and helped me to spot some design flaws. First I sketched out the pattern. Then I sewed the parts together and added padding. I also added the eyelids for the laces and the button on the heel. Furthermore I modeled the sole in the 3D program Fusion360 to fit my foot perfectly and printed it with a 3D printer. I used a really flexible material. In the end I glued the upper onto the sole.

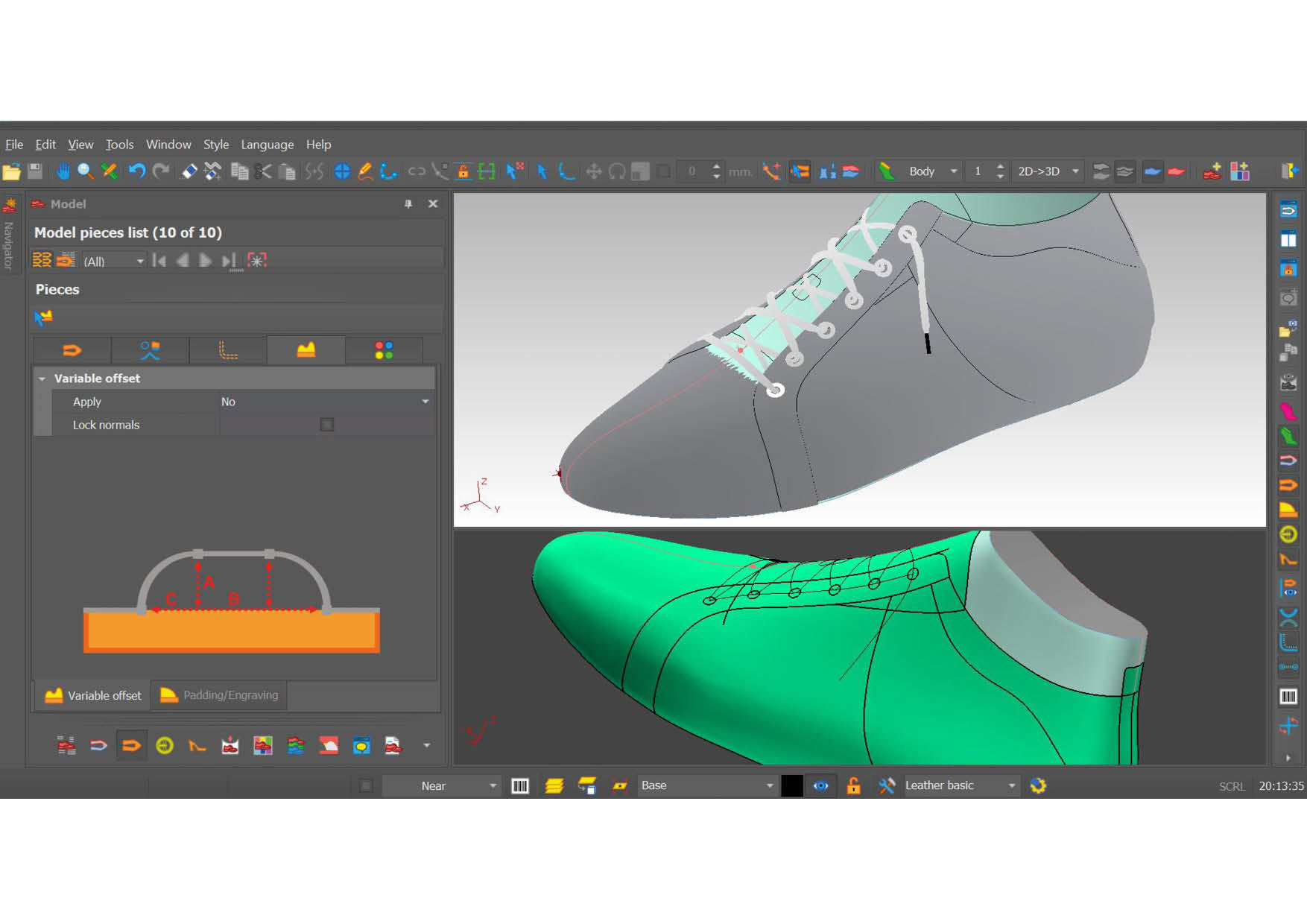

After building the model I also wanted to model a 3D model of my sneaker to get an impression on how the final product would look like. I used the program ICAD 3D+ to model the whole sneaker, including all parts, stitching and laces. Then I imported the model into Keyshot for texturing, lighting and rendering. I used the Vizoo scanner xTex to scan all the textures myself.

The finished 3D model really looks like I imagine the design of the final product. The four customizable versions change the classic base design to four totally different styles.

Different versions:

Basic

Crazy

Cool

Sweet